Naveena Denim Mills and Circular Systems Tap Hemp Waste for Eco Textiles

Pakistan-based denim manufacturer Naveena Denim Mills is taking inspiration from nature to protect the planet with its BluePrint 2030 sustainability strategy.

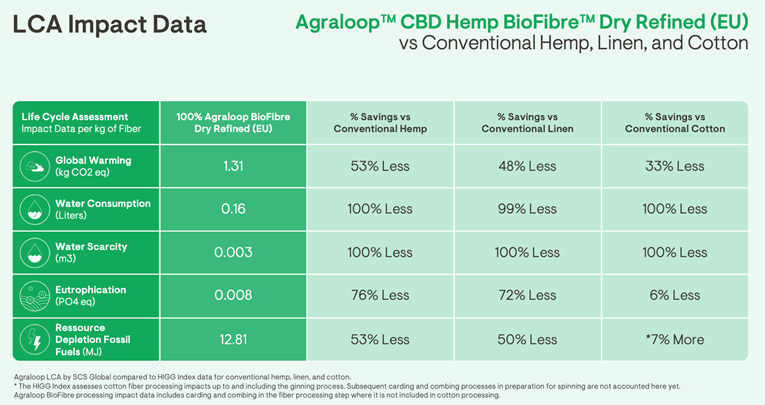

Along with its mission to “champion equitable progress,” Naveena wants to “pioneer ecological harmony” through responsible production and “embrace transparent innovation,” including collaborations. Addressing the last two pillars of BluePrint 2030, NDM has been working with Circular Systems’ Agraloop BioFibre material made from hemp crop leftovers, such as stalks, stems and leaves. This both utilizes waste and reduces the carbon emissions and water usage typically associated with cellulosic fiber production.

Here, Berke Aydemir, head of research and development and technical sales at Naveena Denim Mills, and Isaac Nichelson, founder and chief executive officer of Circular Systems, share how their partnership came about, the impact of this material choice and how NDM is incorporating this innovation into its collections.

Carved in Blue: How did Naveena first link up with Circular Systems? Why did you want to work with the material company?

Berke: While we were looking for sustainable fiber and hemp alternatives in the market, we crossed paths with Circular Systems. Impressed by their innovative offers, we wanted to work with them.

We were particularly interested in Agraloop hemp products, transforming leftovers from crops into high value natural fiber fashion products.

Carved in Blue: It’s a great story to obtain fiber from agricultural waste. How scalable is that method? How much volume could be achieved?

Isaac: Textile fiber from agriculture waste is a massive opportunity. Millions of tons per year are possible. One million-plus acres of oilseed flax and oilseed hemp residues are burned every year in North America alone.

Carved in Blue: Does the eventual hemp fiber obtained from this process have different visual properties in denim than traditional hemp fiber or cottonized hemp fiber?

Berke: We don’t see any difference. The color of the fiber may be slightly different, but this has no effect on the final denim product.

Carved in Blue: Could you share the production method used to turn the waste into fiber? It’s great that it’s waterless, but what footprint does this process have in terms of chemicals used or carbon footprint produced?

Isaac: The Agraloop DryRefined process is entirely natural and mechanical, zero water or chemicals are used in the processing of the fiber.

Carved in Blue: Conventional hemp is difficult to spin and usually needs a support fiber or blending partner. Is this also the case for Agraloop BioFibre? And if so, what are you blending it with?

Berke: When hemp is used in more than a certain percentage, a lot of waste is created, which is not feasible due to both production loss and the use of too much fiber. For this reason, we use 10 to 20 percent of total fabric as the optimum percentage. We generally mix it with fibers such as cotton or TENCEL™.

For example, our Keaton I73 fabrics contain TENCEL™, cotton and hemp content (58 percent cotton, 33 percent TENCEL™ lyocell, 9 percent hemp) 12 oz. in pure dark indigo. They provide an authentic vintage marble denim look. Vintage character is obtained thanks to hemp, and ultra-soft hand feel thanks to TENCEL™.

Carved in Blue: What is the fabric’s hand feel, and is there any yarn irregularity or natural slub character?

Berke: Since we mix it with other fibers, we can get a unique irregular and natural slub appearance. This contributes to the products looking authentic and vintage. Hand feel is similar and even little softer than regular hemp.

Carved in Blue: Circular Systems has other BioFibres that come from crops like banana and pineapple. Is Naveena considering using these other agriculture byproducts in denim production?

Isaac: Circular Systems is currently prototyping at commercial scale with banana and pineapple leaf waste. We anticipate these products to scale up in 2025.

Carved in Blue: How does this initiative fit into your BluePrint 2030 strategy?

Berke: BluePrint 2030 is our commitment to pioneer ecological harmony, champion equitable progress and embrace transparent innovation. Each commitment within this framework comprises distinct focus areas and indicators.

To embrace circularity, we use recycled, upcycled and organic fibers including Agraloop in our products. We aim to continue our journey towards building regenerative systems and make our products and value chains traceable.